Pearlson Shiplift Corporation employs the most experienced team of Shiplift Field Engineers in the World. These individuals represent the best-of-the-best in terms of knowledge and know-how related to Shiplift and Transfer Systems, as well as some of the best minds in the Operation, Maintenance and Dockmaster Training fields.

Pearlson Shiplift Corporation currently provides support and maintenance services to over 90% of the active shiplifts around the World. These visits range from annual inspections, to long-term maintenance contracts to support Certification that may include visits every quarter.

No matter what the requirement is, the Pearlson Field Engineering team is ready to support. These include both Commercial shipyard customers, as well as Governmental / Defense Organizations.

Pearlson Shiplift Corporation firmly believes in the practice of “knowledge transfer”. When our team is engaged in order to provide Operation & Maintenance Training, we do so in order to better educate our customers on how their system works, and what steps they can take to make it better.

One of the inherent benefits of a Pearlson Shiplift System is the longevity in which our system operates. With shiplift and transfer systems still operating today, which were originally installed more than 50+ years ago, the additional focus of training shipyard personnel on how best to maintain their system is a critical part of a successful operation.

Pearlson Shiplift Corporation is pleased to provide our customers with both classroom based and hands-on curriculum related to dockmaster training.

Our team of dockmasters have been deployed all around the world to instruct our shipyard customers how to perform docking calculations, blocking arrangements, stability calculations and more. Following the completion of the dockmaster training course, a certificate is issued to all participants.

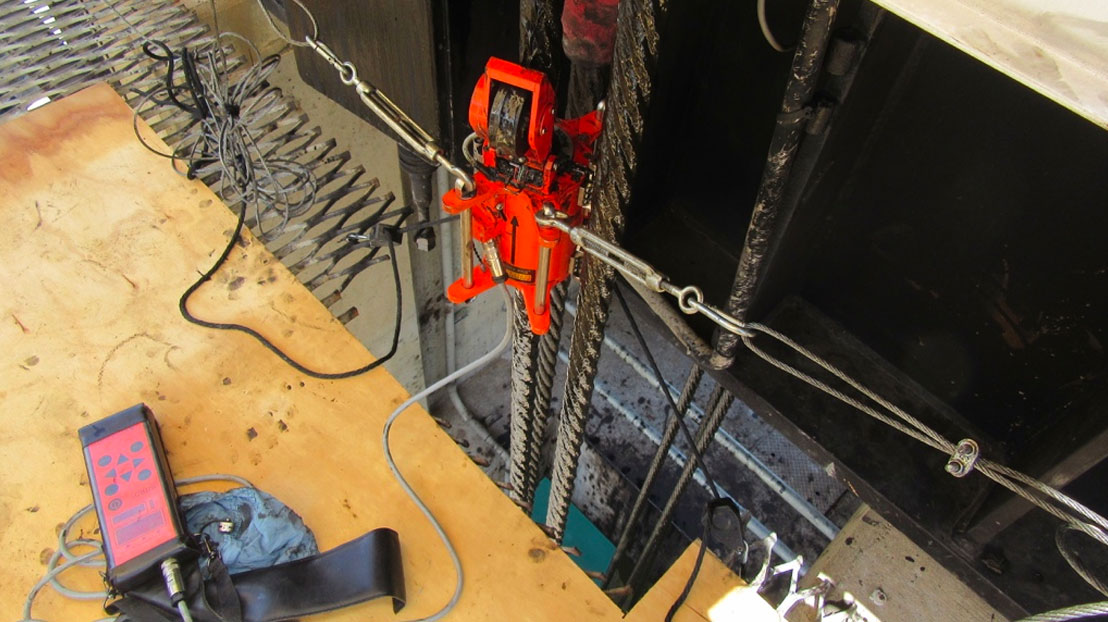

Pearlson Shiplift Corporation is pleased to offer our customers the additional service of conducting Non-Destructive Testing (NDT) of Wire Rope Assemblies. This service enables the customer to see what is happening “inside” the wire rope assembly in order to make better informed decisions about change-out and maintenance periods.

The completion of Wire Rope NDT also enables shipyards to keep wire rope assemblies in use for a greater period of time, in accordance with Lloyd’s Register Codes and Standards.